Introducing AFTERLIFE project video about its methods and potential impacts:

The AFTERLIFE consortium demonstrates a new way of wastewater treatment that simultaneously recovers compounds of interest while converting remaining organic matter into a high-volume added value bio-based polymer.

Find the full article here: www.renewable-carbon.eu/news/converting-wastewater-into-bio-based-polymer-essential-oils-phenolic-extracts-and-clean-water-the-afterlife-project-presents-its-results

Here you can find all the public deliverables produced during the AFTERLIFE project

D.7.1. Hot spot LCA analysis for further optimisation

D.7.2. Final Life-cycle assessment

D.7.3. Hot spot analysis for further optimisation

D.7.4. Final Techno-economic assessment

D.7.5. Social and socio-economic impact of the processes and products

D.8.6. Dissemination and exploitation activities

The AFTERLIFE pilot plants have been operated for the validation of the technology at technology readiness level (TRL) 5. The pilot lines have been deployed at BBEU premises in Belgium for the processing of the four wastewaters included in AFTERLIFE:

The treatment capacity of the operated pilots was 1 cubic metre of wastewater per day.

Jake Wastewater Line at BBEU

Heritage Wastewater Line at BBEU

The Jake wastewater line (confectionery industry) and the Heritage wastewater line (cheese manufacturing) were focused on the conversion into biopolymers (PHA) while Citromil wastewater lines (citric fruit processing) have been considered as more promising for the recovery of value-added compounds, such as essential oils and phenolic-rich extracts.

Citromil JL Wastewater Line at BBEU

Citromil EO Wastewater Line at BBEU

The different pilot lines have been operated sequentially and stopped at the end of August 2021. The production of essential oils and phenolic extracts was well aligned with the lab-scale experiments as well as filtration, which have been adapted to the available equipment, and anaerobic fermentation steps. Besides, different alternatives have been tested for PHA production to overcome the challenges found at the pilot scale.

Two main groups of products are obtained in AFTERLIFE:

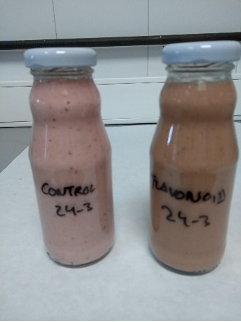

Essential oils and phenolic extracts have been produced by CELABOR and tested by CTC in food products, including:

The antimicrobial, antioxidant and organoleptic properties have been evaluated for each product with good results for most of them.

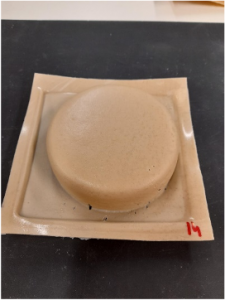

The production of PHA-based materials has been performed by Lurederra. The PHA has been combined with another bio-based polymer to improve their mechanical properties. The obtained material has been used successfully by CELABOR for the production of plastics trays for food packaging.

Plastic Tray produced by CELABOR

AFTERLIFE was presented at the BBI JU stakeholder forum on 3-4 December 2019 in Brussels. This public event brought together the bio-based industries community and facilitate open discussion on the impact, achievements and strategic direction of the BBI JU projects. AFTERLIFE presented at the stand and Dr. María López gave a presentation about the project. (In the picture: Dr. María López and Dr. Seena Koyadan at the AFTERLIFE stand)

The third general assembly and first exploitation workshop was hosted by CSIC in their building located at Madrid. The consortium thanks to CSIC for hosting.

AFTERLIFE webinar  slides presented on 15 October 2019 by the AFTERLIFE team. This webinar was addressed on the following topics: 1) Filtration, solvent extraction and steam extraction, with an eye on the big numbers. 2) Recovery and natural compounds of interest from agrifood wastes. Click here to download the slides.

slides presented on 15 October 2019 by the AFTERLIFE team. This webinar was addressed on the following topics: 1) Filtration, solvent extraction and steam extraction, with an eye on the big numbers. 2) Recovery and natural compounds of interest from agrifood wastes. Click here to download the slides.

More information about the webinar here

AFTERLIFE has been presented in the IWA Resource Recovery 2019 conference in Venice on 11th September 2019. The project objectives and initial results have been explained in a presentation entitled “Compounds of interest in wastewater from food processing industries: H2020 AFTERLIFE project” in the session “Road to biorefinery and WRRF implementation”. Besides that AFTERLIFE was represented in a poster about the work developed by NOVAID in the production of PHA using mixed cultures. The poster entitled “Selecting a PHA Accumulating Mixed Microbial Culture Using Fermented Wastewater from a Sweets Manufacturing Industry” was part of the poster session at the conference. Finally, AFTERLIFE was also present in the stand of INNOVEN in the conference that has received the visits of the members of the consortium that have attended the conference (pictures above).

The second general assembly was hosted by Celabor in their facility located at Herve, Belgium. Very constructive meeting and visit to the laboratory facility. The consortium thanks to Celabor for hosting.

AFTERLIFE’s first general assembly meeting was held in Espoo, Finland. Consortium partner VTT hosted the meeting. Members have great discussions and after the meeting, we enjoyed the VTT facility visit.

The AFTERLIFE Kick-off meeting was held on September 11th and 12th, 2017 at Hotel Palace, Via F. Lombardi, 13 – 70122 Bari, Italy

The food and drink industry is the third most water-thirsty industrial manufacturing sector in Europe. It uses around 4.9 m3 of water per inhabitant per year and generates around 3 700 million m3 of waste water annually. This waste water contains organic molecules and other potentially harmful particles that could pollute the environment. However, there is an alternative. Waste water from the industry contains valuable molecules that could also be extracted and given a second life, turning the water into a resource and helping to integrate the food and drink industry into the emerging circular economy. EU-funded project AFTERLIFE is developing innovative technology that will filter and extract valuable elements from the waste water and convert them into bioplastics and food additives, as well as purifying the water. Read more about the article published on the EC website. (BBI JU website)

Wastewater treatment and reuse is not new, and knowledge on this topic has evolved and advanced throughout human history. Since prehistoric civilisations have been capable of reusing untreated municipal wastewater, especially for the land application, wastewater treatment became a common practice within all human settlements. The process has been optimizied due to a growing understanding of the issue and the development of treatment technologies. Since industrial advancement occurred, waste production from industries has deeply affected our society. Read more about the article appeared in BE Sustainable magazine

Click here to download the magazine ( in Spanish)

AFTERLIFE, a 4 million € EU project focused on finding an integrated solution for the recovery and conversion of relevant fractions from wastewater, was officially launched Monday, September 11th. Led by EggPlant Srl, the project consortium is comprised of 15 partners from 7 European countries. On September 11th and 12th the official kick-off was held for the Afterlife project in Bari, Italy. Scientists at companies and research institutes will be cooperating for the next four years to find an integrated solution for the recovery and conversion of relevant fractions from wastewater. Click here to read the entire press release at Bio-based news.

The AFTERLIFE project (Advanced Filtration TEchnologies for the Recovery and Later conversIon of relevant Fractions from wastEwater) was launched on September 11th-12th 2017 on invitation of the Italian company EggPlant in Bari (Italy), the coordinating site of this new project from the EU H2020-BBI-JTI-2016 call. Read more about the press release from CSIC here

| Title | Size | Date added | Download |

|---|---|---|---|

| 21-01-08_Afterlife+sponsor_logos | 14.43 mb | 08 - 01 - 2021 | Download |

| 18-06-22_AFTERLIFE process_A0 | 1.07 mb | 25 - 06 - 2018 | Download Preview |

| 18-06-22_AFTERLIFE leaflet_A4_2 pages | 845.55 kb | 25 - 06 - 2018 | Download Preview |

| 18-06-13_afterlife_leaflet_6pages | 1.03 mb | 14 - 06 - 2018 | Download Preview |

| 17-11-07_Afterlife_RGB | 97.00 kb | 20 - 02 - 2018 | Download Preview |

| 18-02-19-Afterlife-Rollup | 6.83 mb | 20 - 02 - 2018 | Download Preview |