Objective

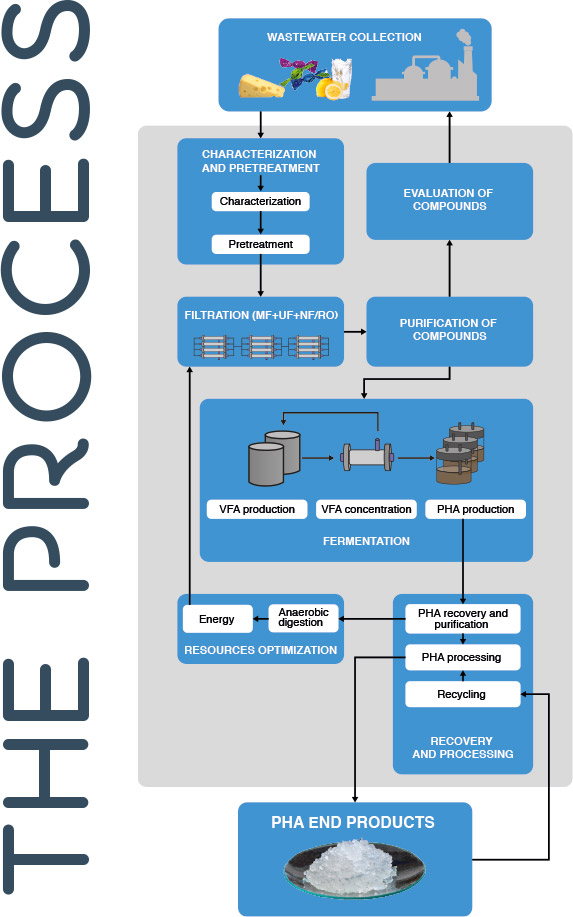

The overarching objective of the AFTERLIFE project is to demonstrate, at TRL-5, an innovative wastewater treatment that simultaneously recovers compounds of interest while converting the remaining organic matter into a high-volume added value biopolymer. Specifically, it sets out to:

- Develop the filtration system for recovering suspended and soluble solids in wastewater by using membrane filtration units.

- Develop the process for recovering and purifying valuable compounds in the concentrates extracted in the filtration step.

- Develop an anaerobic/aerobic process for converting the low value-added organic matter into PHAs.

- Optimize the resources in the process, following a circular economy approach

- Design and optimize the AFTERLIFE process from a holistic perspective following a Multidisciplinary Design Optimization (MDO) approach

- Conduct a demonstration, at a pilot scale, using real industrial wastewater to generate the end products

- Prove the economic and industrial feasibility for AFTERLIFE process along with a comprehensive Lifecycle Analysis (LCA) and cost assessment.

- Promote exploitation of the project’s results and expand its impact.